High Temperature Elastomer Injecting Machine

|

Main Technical Parameters

|

||||

|

Model No

|

Out put

(g/s) |

Material Tank

Volume

(L) |

Mixing Ratio

(P:I) |

Total Power

(KW) |

|

LZ-302A

|

5-15

|

50

|

100:10-25

|

18

|

|

LZ-302B

|

10-30

|

100

|

100:10-25

|

20

|

|

LZ-302C

|

100-350

|

120

|

100:10-258

|

22

|

|

LZ-302D

|

100-350

|

200

|

100:10-25

|

28

|

Welcome to call 137-5172-5551, Consulting and ordering

Description

Product Use

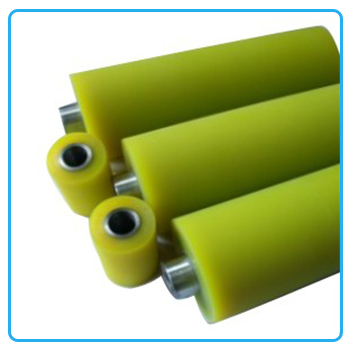

It is used for manufacturing injected polyurethane elastomer products, such as polyurethane bars used for

metal stamping molds, various heavy load wheel seals used for metallurgy, printing and dying, textile and

paper making industries, and highly wear resisting materials used for the sliding wheels of sliding carriages

and carts.

Product Features

· Twin electric heating and heat conduction oil circulation system; from circulation pump, interlayer of the primary material pot,

metering pump, filter, to injecting head, the material is heated by heat conduction oil all the time, so as to ensure stable

temperature.

· A material pot with an acid resisting stainless steel interior and a heating interlayer is used; a tubular electric heating device is installed inside the interlayer; the material pot is equipped with a drying device to prevent moisture.

· We guarantee that our products have no visual air bubbles: The vacuum system is performance excellent and reliably sealed. The patented mixing head will not produce air bubbles at high speed stirring.

· A material pot with an acid resisting stainless steel interior and a heating interlayer is used; a tubular electric heating device is installed inside the interlayer; the material pot is equipped with a drying device to prevent moisture.

· We guarantee that our products have no visual air bubbles: The vacuum system is performance excellent and reliably sealed. The patented mixing head will not produce air bubbles at high speed stirring.

Application Scope